Infinita

All Projects | Speculative Ideas

Infinita - Capstone Project SCAD

How might we make upholstery more sustainable?

‘A person’s aesthetic is the formal dimension of the unique way in which he or she experiences, responds to and engages with the world.’ Immanuel Kant

Problems

Environmental Impact: The process of renovating the item is time-consuming and difficult - this incentivizes waste.

Personalization: The need for self-expression has faster recurrence within Millenials and it is not met by furniture’s permanence.

Retail Innovation: Lead times are long and keeping inventory is expensive, but people want to take items home the same day.

Nomadic Living: Heirlooms are difficult to keep as people move houses and locations more often than before.

What happens if we split the product into parts and sell them separately?

Environmental Impact: Less Labor and waste if one frame can be reused easily multiple times

Personalization: You could change the size and look of the item and space anytime by exchanging parts.

Retail Innovation: It would be easier to keep inventory and innovate in the customer retail experience.

Nomadic Living: You would have a more versatile product that is easier to sell, return to the company or even take with you.

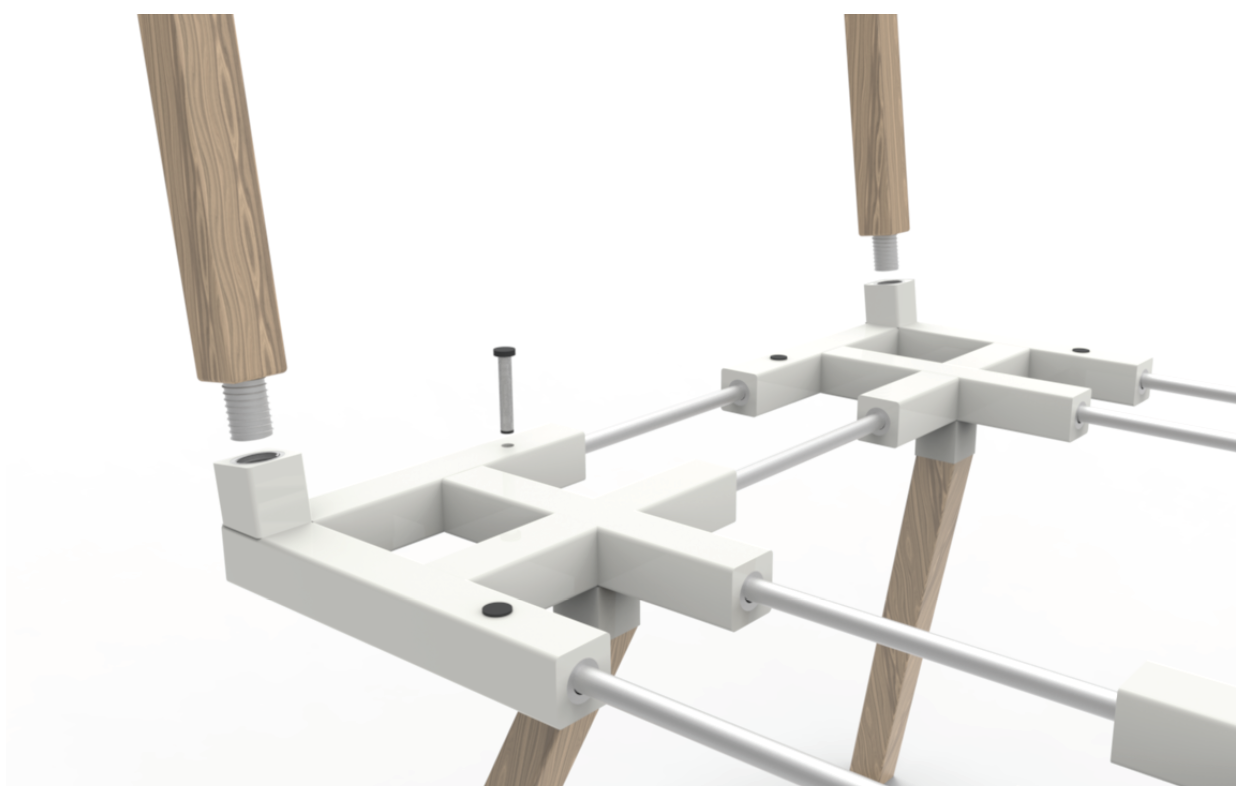

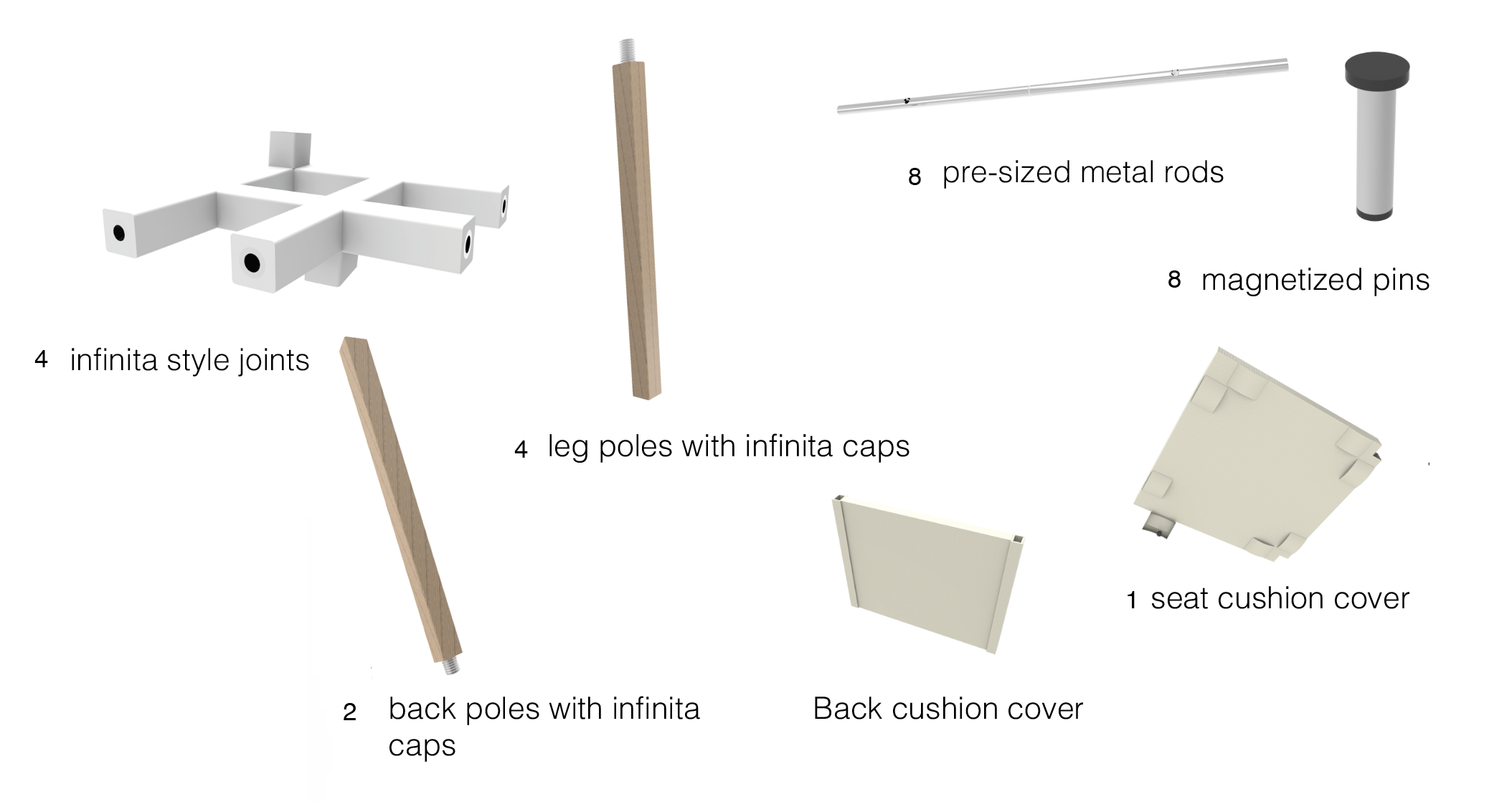

Size Transformation

The four Infinita joints are able to telescope to allow the chair to change in size. The pins hold the telescoping rods and joints together by fixing them into preset sizes. The legs and arms screw into the joints as well; these can change in shape and size if wanted, in order to change the look of the chair. In this way we could potentially switch a dining chair into a lounge chair or sofa if we need, making the space completely adaptable. It would be possible also to think about this as a robotic system instead of a manual alteration.

The dining chair could turn into a lounge chair or sofa if we need it, making the space completely adaptable. It would be possible also to think about this as a robotic system instead of a manual alteration.

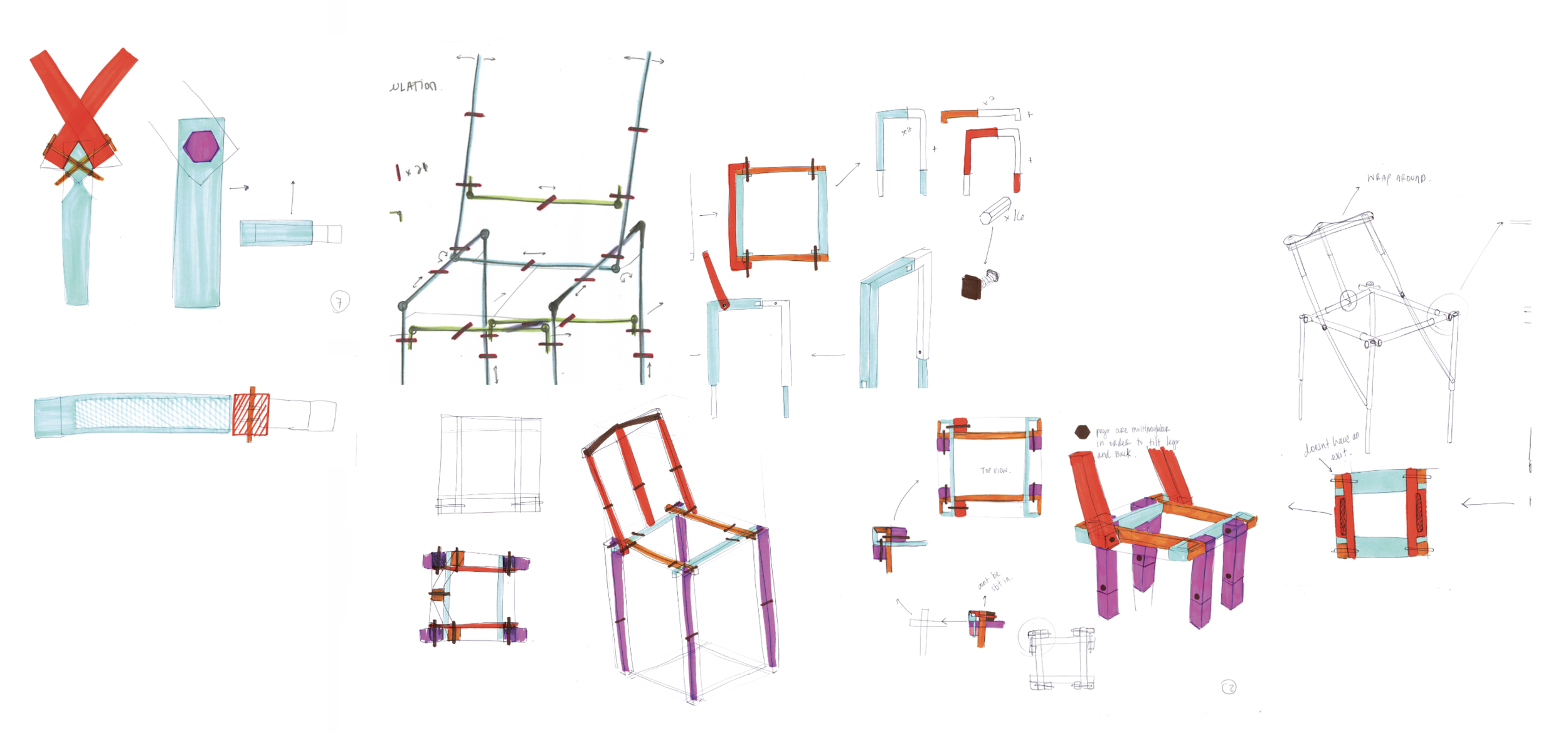

The Mannequin

I was looking for the simplest and most versatile shape that would allow for the tailoring of chair sleeves around it. All the parts had to be sold and recycled separately, which meant no glue. To be a mannequin, it needed to be adaptable, and so I had to look at the joints needed for transformation. It had to allow for shape and size transformation, by expanding and contracting but also giving enough points of contact for the sleeves to attach. The solution presented consists of 28 parts that together make a chair mannequin. They can be assembled, disassembled and exchanged anytime, making it a never-ending adaptable and renewable product.